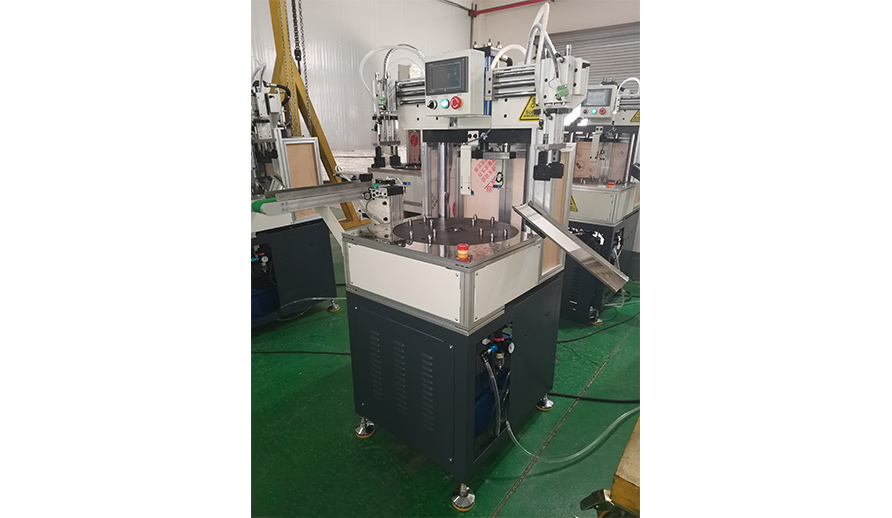

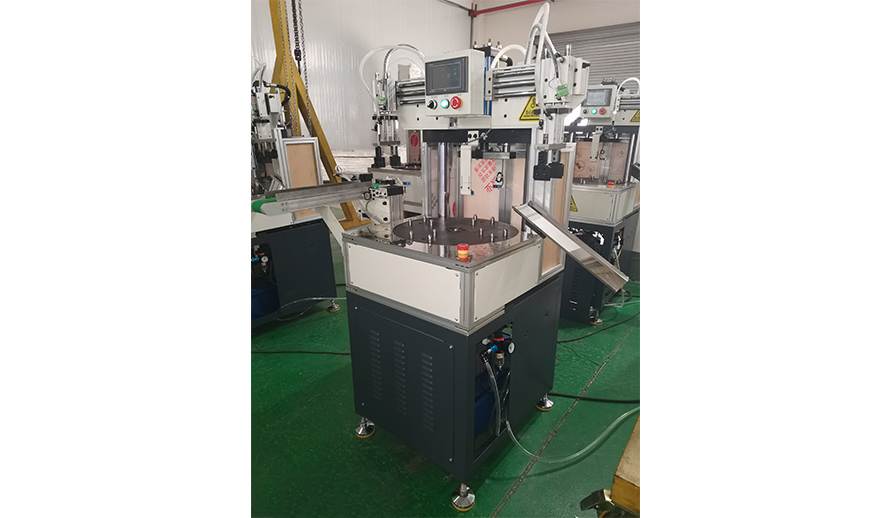

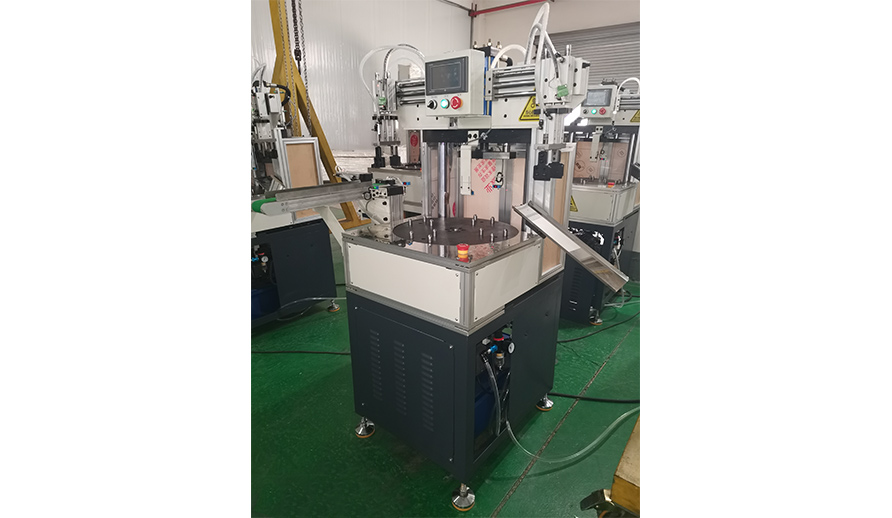

Four-Station Stator Press And Insertion Machine

- Product Information

Four-Station Stator Press And Insertion Machine is an innovative piece of equipment designed to streamline the production process of electric motor stators. As a leading Manufacturer, we take pride in our commitment to delivering high-quality machinery that enhances the efficiency and precision of stator manufacturing.

Four-Station Stator Press And Insertion Machine is an advanced equipment launched to meet the needs of shaded-pole motors and inner-wound stator motors, and realizes the riveting of the main and auxiliary stators. It adopts an eight-point turntable structure to separate the human hands from the riveting station to improve the safety factor. The work is simple and easy to operate, and the efficiency is three times that of manual operation.

Technical Specifications:

| Item | Technical Specifications |

| Function | Realize The Riveting Of The Main And Auxiliary Stators; Automatic Unloading; Automatic Loading Of The Upper Stator |

| Application Areas | Shaded Pole Motors, External Rotor Motors, Etc. |

| Efficiency | 2.3-3s/Piece |

| Compatibility | Change Varieties In 5 Minutes;48/58/60 Full Range Of Varieties |

| Power | 3kw |

Equipment Features:

1. Stability: Use Box-Type Turbine Reducer + Cam Divider To Drive The Indexing Plate To Ensure Stable Operation Of The Equipment

2. Safety: All Mechanical Moving Structural Parts Are Protected With Protective Covers To Ensure Safe Operation.

3. High Efficiency: The Production Cycle Can Reach 2.3-3s/Piece; The Main Stator Is Automatically Loaded

4. Intelligence: Automatically Senses Materials. When There Is No Material At The Work Station, The Pressure Head Automatically Stops Working.

5. Humanization: The Human-Machine Interface Displays Each Row Of Operating Data, And Related Management Work Becomes Simple. You Only Need To Collect Data From The Human-Machine Interface (Such As Output, Etc.)

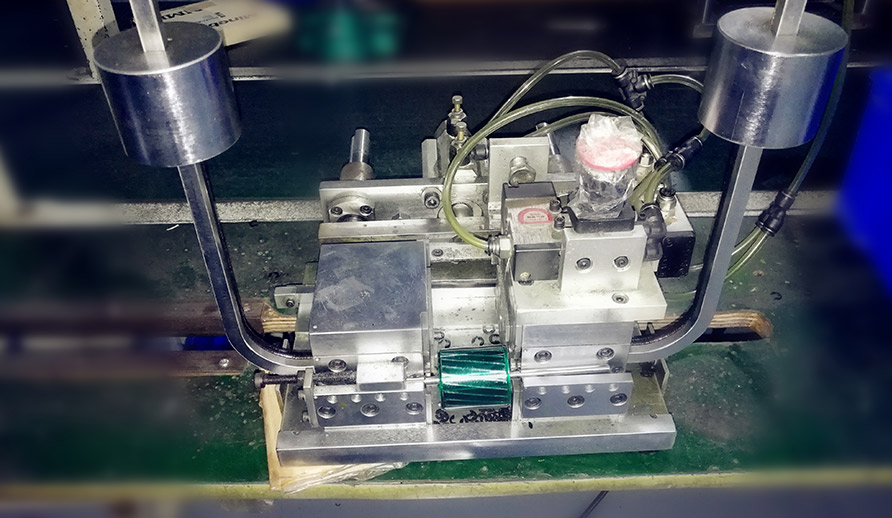

Processing Product Diagram: