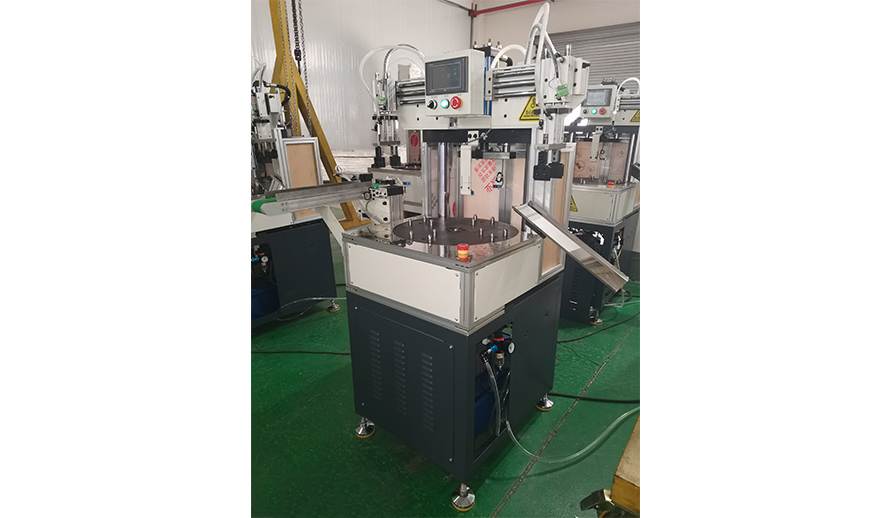

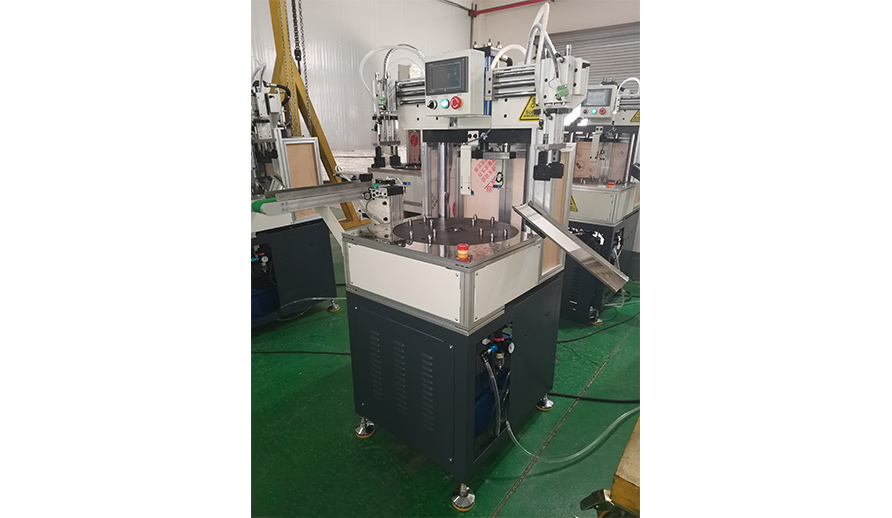

Precision Servo Stamping Machine

- Product Information

The Precision Servo Stamping Machine represents the pinnacle of stamping technology, tailored to meet the rigorous demands of industries requiring absolute precision and repeatability, such as the motor manufacturing, automotive, and home appliance sectors. This advanced servo stamping machine is meticulously engineered to perform intricate tasks, including motor bearing insertion, motor housing riveting, and stator riveting for both main and auxiliary stators.

At the core of the precision machine's capabilities is an AC servo motor driving a low-backlash ballscrew and press punch. This configuration, in concert with high-sensitivity sensors and an advanced PLC control system, enables the equipment to monitor, adjust, and control stamping loads with unmatched accuracy. The result is high-repeatability processing quality, essential for producing components that meet exacting standards. As a leading China servo stamping machine manufacturer, our factory embodies strength and expertise, dedicated to delivering high-precision solutions for the motor, automotive, and home appliance industries.

Precision Servo Stamping Machine Technical Specifications:

| Item | Technical Specifications |

| Function | Realize Automatic Riveting Of Products, Such As High-Precision Riveting Of Motor Shafts Into Rotors, Bearings, Riveting Shells And Other Products |

| Repeat Accuracy | 0.02mm |

| Efficiency | 4-5s/Piece |

| Compatibility | Standard Machine, Applicable To A Variety Of Scenarios |

| Power | 3kw |

Precision Servo Stamping Machine Equipment Features:

1. Advanced PLC Control: The system's PLC control panel ensures the entire stamping process is automated, with stroke and operation parameters fully adjustable, allowing for a seamless, consistent performance.

2. AC Servo Motor Precision: The machine’s servo motor delivers stable, consistent force application, ensuring both speed and precision. This design maintains exact pressure for each stamping stroke, crucial for maintaining product quality in mass production.

3. High Efficiency & Reliability: With its efficient energy use and robust construction, the Precision offers optimal performance and durability, reducing downtime and maintenance needs while increasing throughput.

4. Flexible Application Range: Designed for flexibility, this machine easily adapts to various stamping applications, including rivet stamping, bending, and forming, making it suitable for a wide range of components within the motor and auto parts industries.

Precision Servo Stamping Machine Detail Images: