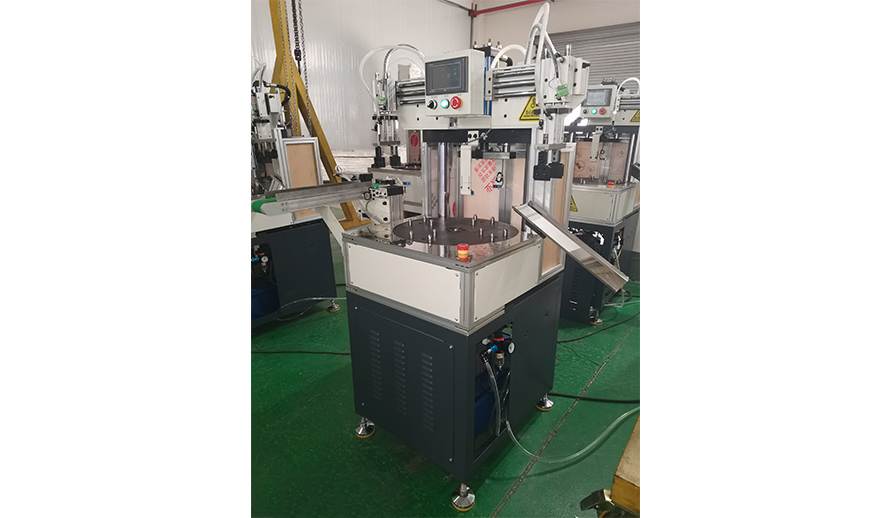

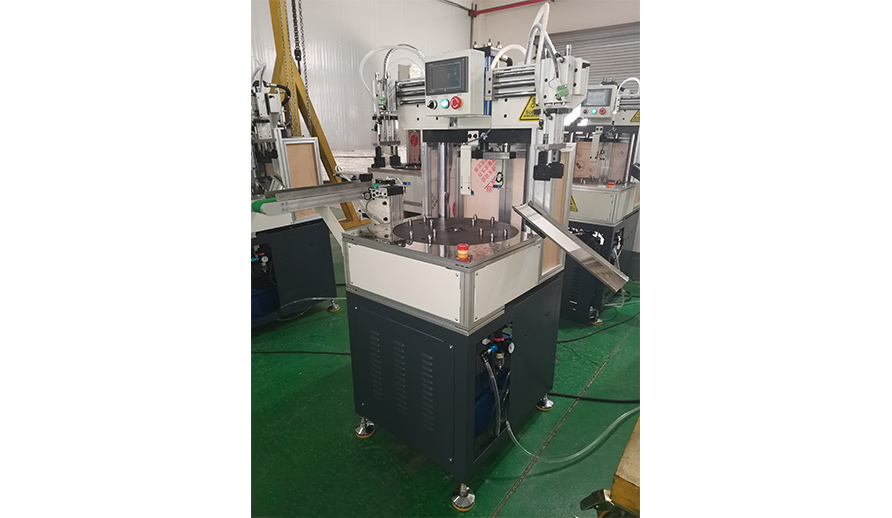

8 Multi-Station Stator Assembly System

- Product Information

The 8 Multi-Station Stator Assembly System is a cutting-edge, high-precision machine designed to elevate the standards of electric motor stator manufacturing. Engineered for modern production environments, this automated machine optimizes the pressing and insertion process, ensuring each stator meets rigorous quality standards with unmatched efficiency and accuracy.

With an eight-station operation, the stator assembly system enables simultaneous processing at multiple stages, significantly enhancing production throughput while minimizing manual intervention. This multi-position stator press performs high-precision riveting of stator components, precisely aligning and securing each part to ensure durability and operational excellence.

Designed specifically for shaded-pole and inner-wound stator motors, the system incorporates a robust eight-point turntable structure. This innovative feature separates the worker’s hands from the riveting station, prioritizing safety without compromising on efficiency. The stator assembly system is user-friendly, requiring minimal training to operate, and is up to three times more efficient than manual processes, making it an essential asset for high-demand manufacturing lines.

Additionally, the 8 system offers cost efficiency, providing a sophisticated solution at a relatively low equipment cost, making it an excellent investment for manufacturers seeking high returns on production efficiency, safety, and product quality. As a leading China stator assembly system manufacturer, we bring unparalleled expertise and precision engineering to the stator production industry.

8 Multi-Station Stator Assembly System Technical Specifications:

| Item | Technical Specifications |

| Function | Realize Riveting Of Main And Auxiliary Stators; Automatic Blanking |

| Application Areas | Shaded Pole Motors, External Rotor Motors, Etc. |

| Efficiency | 2.3-3s/Piece |

| Compatibility | Change Varieties In 5 Minutes;48/58/60 Full Range Of Varieties |

| Power | 2.2kW |

8 Multi-Station Stator Assembly System Features:

1. Stability: Use box-type turbine reducer + cam divider to drive the indexing plate to ensure stable operation of the equipment

2. Safety: All mechanical moving structural parts are protected with protective covers to ensure safe operation.

3. High efficiency: the production cycle can reach 2.3-3S/piece

4. Intelligence: Automatically senses materials. When there is no material at the work station, the pressure head automatically stops working.

5. Humanization: The human-machine interface displays each row of operating data, and related management work becomes simple. You only need to collect data from the human-machine interface (such as output, etc.)

Processing Product Diagram: