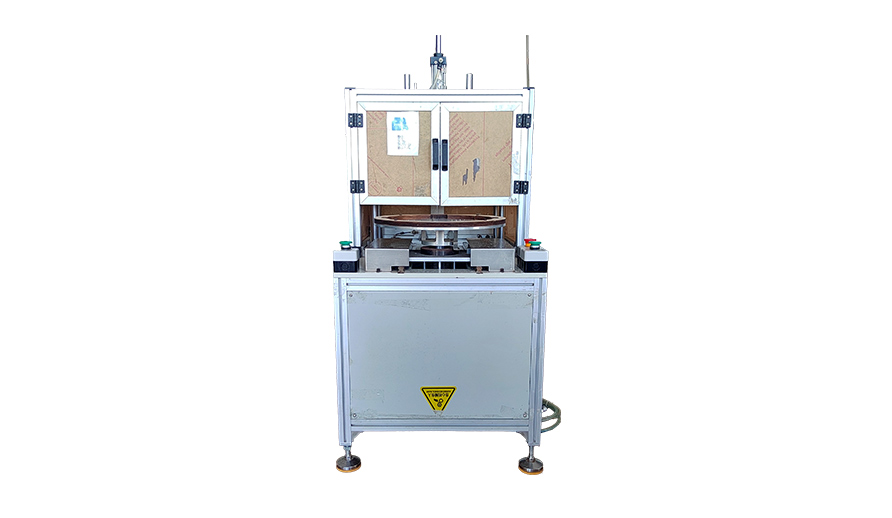

Automatic Epe Pearl Cotton Punching And Cutting Machine

- Product Information

The Automatic Epe Pearl Cotton Punching And Cutting Machine for pearl cotton is an advanced equipment. It is the first in the industry to adopt servo press and is equipped with an automatic loading line. It can automatically feed and complete the punching work. The punching thickness can be arbitrarily selected between 15-110mm. After reasonable configuration, one person can operate multiple devices, with low management cost and high efficiency.

Technical Specifications:

| Item | Technical Specifications |

| Function | The servo press drives the knife template to complete the blanking of pearl cotton products. |

| Size | 1000mm*1300mm*1700mm |

| Workbench Size | L700*W700*H100mm |

| Equipment quality | 1600KG |

| Working voltage | three-phase AC380V |

| Rated air pressure | 0.5±0.1Mpa |

| Rated power | 4KW |

| Work efficiency | 4-5S/piece |

Equipment Features:

1. Advanced Technology, The Industry Is The First To Use Servo Press To Complete The Action.

2. Safety: Only Manual Loading Is Required, No Personnel Operation Is Required, Avoiding The Risk Of Disability Caused By Manual Operation Of The Punch Press.

3. Efficient: One Person Can Watch 2-3 Machines And Just Put The Materials On The Assembly Line.

4. Fully Automatic: Only Manual Feeding Is Required, And The Equipment Completes The Work Fully Automatically, Reducing Dependence On Skilled Workers And Improving Safety.

5. Strong Scalability, Reserve The Automatic Waste Discharge Machine Port For Automatic Waste Discharge Equipment.

Automatic Deburring Machines Application:

1. Efficient Production Line Integration: Our machine seamlessly integrates into existing manufacturing lines, designed to work in harmony with other equipment to maintain production efficiency and reduce downtime .

2. Automated Waste Discharge: The machine is equipped with an automatic waste discharge system, which minimizes manual handling and speeds up the production process, ensuring a clean and organized work environment .

3. Customizable Punching Patterns: It supports a variety of punching patterns and sizes, catering to the diverse needs of different products, from protective packaging to specialized cushioning materials .

4. High-Speed Operation: With a punching speed that can be adjusted according to production requirements, the machine maximizes output without compromising on quality .

Automatic Deburring Machines FAQs:

What materials can the Automatic Epe Pearl Cotton Punching and Cutting Machine handle?

Our machine is designed to efficiently process EPE (Expanded Polyethylene) materials, which is widely used for its cushioning and insulation properties. It can handle various thicknesses and densities of EPE to meet diverse production needs.

How does the machine ensure precision in cutting and punching?

We utilize advanced computer-aided control systems that guarantee high precision in both punching and cutting operations. The machine is equipped with precision guides and sensors to ensure accuracy in every cut and punch.

What is the production capacity of your machine?

The production capacity varies depending on the specific model and settings, but our machines are designed for high efficiency, capable of producing thousands of units per hour, ensuring you meet tight deadlines and high-volume orders.

How easy is it to operate the Automatic Epe Pearl Cotton Punching and Cutting Machine?

Our machines are designed with user-friendliness in mind. They come with an intuitive control panel and comprehensive operation manuals. Additionally, we provide training sessions to ensure your operators are fully equipped to use the machine efficiently.

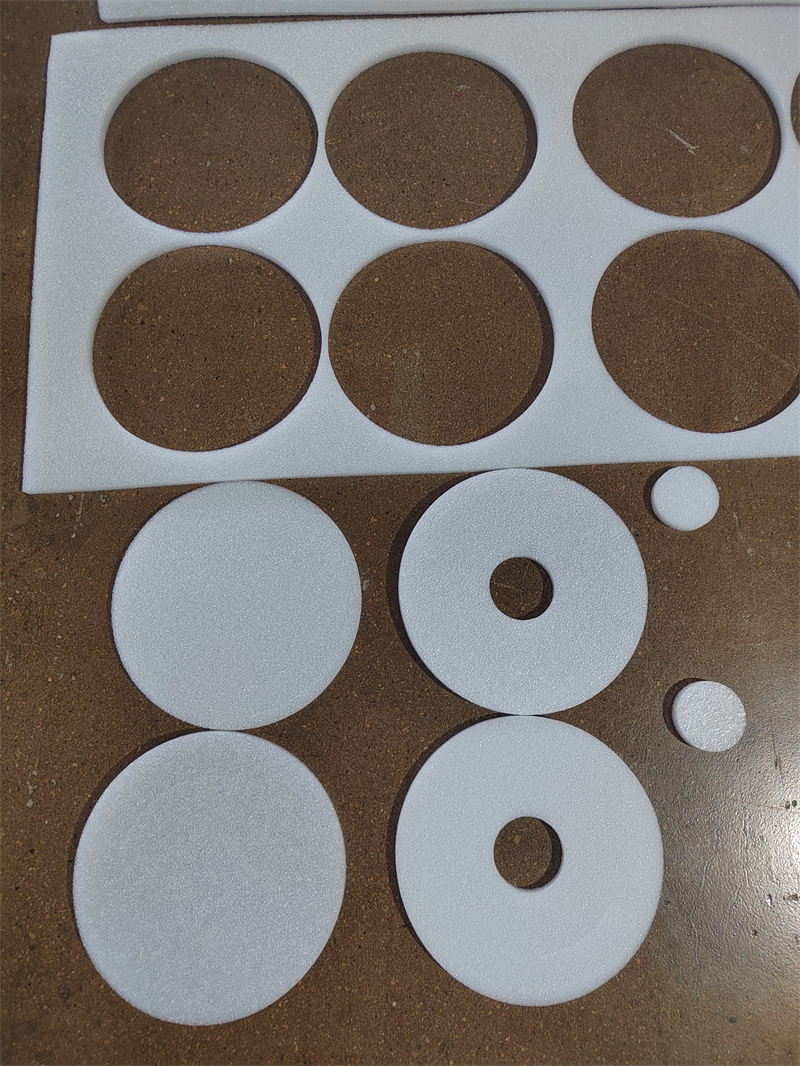

Detail Images:

Processing Product Diagram: