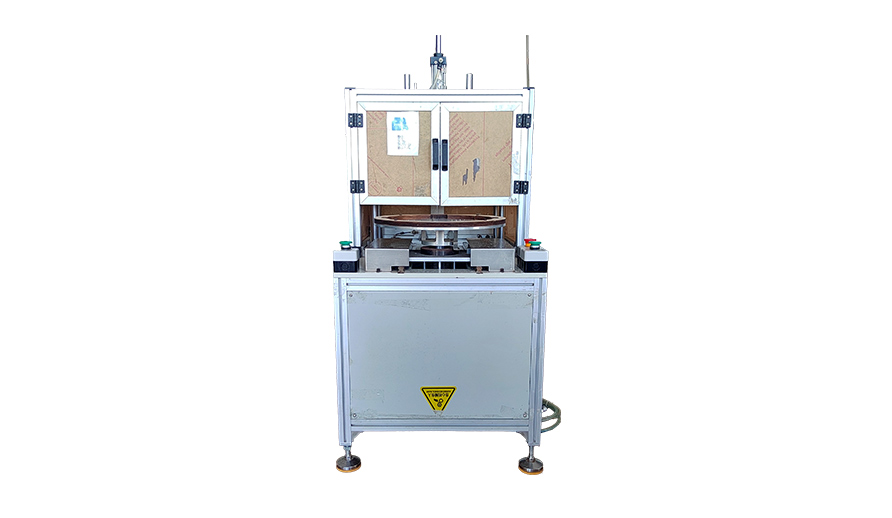

Double-Headed Automatic Pearl Cotton Laminating Machine

- Product Information

Double-Headed Automatic Pearl Cotton Laminating Machine is designed to streamline the lamination process of EPE foam with various materials such as PE film, aluminum foil, and plastic-coated fabrics, without the need for adhesives, resulting in a clean, eco-friendly, and efficient process. The machine's operational principle involves taking the upper EPE layer, thinning it, and then quickly laminating it with the lower EPE layer using a high-speed heating plate, significantly reducing manual labor and improving production speed and quality.

Double-Headed Automatic Pearl Cotton Laminating Machine is an advanced special equipment in the industry. Through the characteristics of the material itself, it can achieve double or multi-layer lamination of EPE pearl cotton without adhesive. The industry takes the lead in adopting a dual-manipulator design, taking turns to use the same station to give full play to the value of the equipment. One device is equivalent to the efficiency of two devices. It is the most advanced solution in the industry, easy to use, stable and reliable.

Technical Specifications:

| Item | Technical Specifications |

| Function | Achieve single or multi-layer cold ironing and lamination of pearl cotton, double-head operation |

| Efficiency | 6S/piece |

| Size | 3300*1400*2400mm |

| Power | 25kw |

Equipment Features:

1. High Efficiency, Double-Head Operation, Making Full Use Of Time Gaps, And The Efficiency Is Doubled Compared With Traditional Laminating Machines.

2. Intelligent: Automatic Counting, Temperature Display

3. Powerful Function: Through Program Selection, Multiple Layers Of Pearl Cotton Can Be Completed At The Same Work Station, Reducing The Workload Of Material Turnover.

4. Humanization: The Human-Machine Interface Displays Each Row Of Operating Data, And Related Management Work Becomes Simple. You Only Need To Collect Data From The Human-Machine Interface (Such As Output, Etc.)

Detail Images:

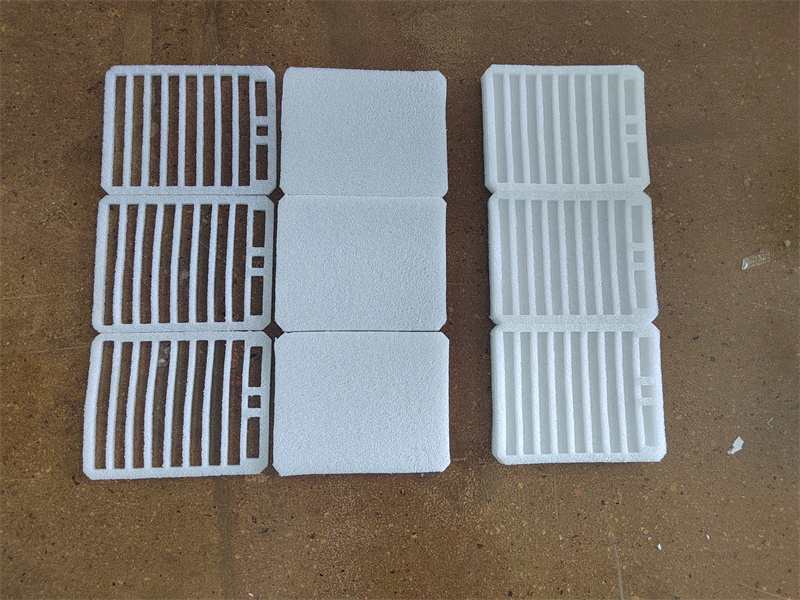

Processing Product Diagram: