Complete Automatic Wooden Hanger Making Line

- Product Information

Complete Automatic Wooden Hanger Making Line

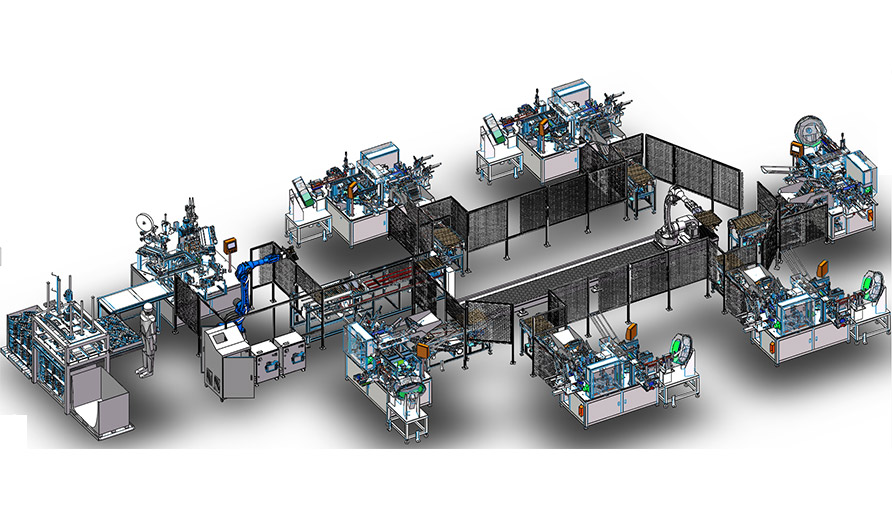

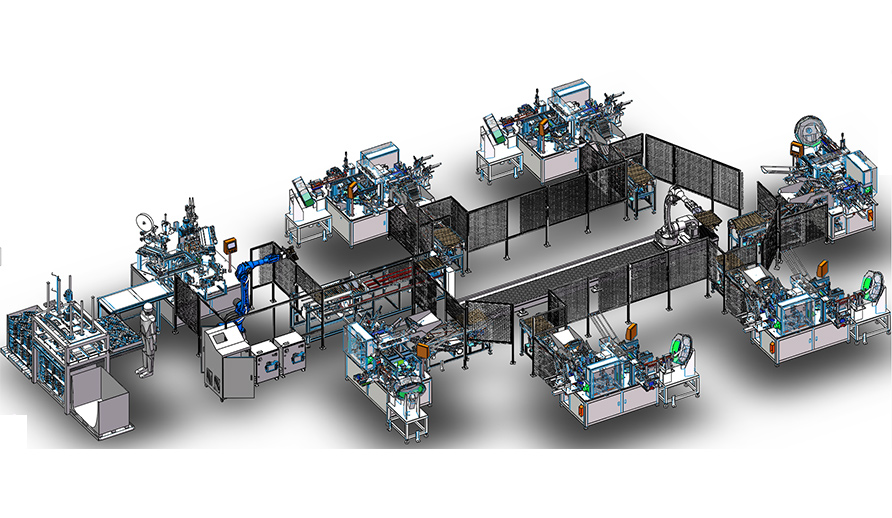

Automatic Wooden Hanger Making Line can automatically complete the nailing, hooking, logistics, bundling, screening and packing of wooden hangers. It is the world's leading complete automatic equipment and the first fully automatic equipment in the industry, with many invention and utility model patents. The promotion of the whole set of equipment has profoundly changed the production mode of wooden hangers, reducing four-fifths of the labor force, ensuring stable and consistent quality, shortening the production cycle, and greatly saving space due to centralized packaging and warehousing. It turns heavy and skilled work into a simple and easy-to-learn workstation, greatly reducing management costs, and through a series of optimizations, we get high-quality and low-priced products. Weike Intelligent Equipment is determined to find a reliable, complete and systematic solution for the production and processing of the hanger industry, and has achieved initial results.

Automatic Wooden Hanger Making Line Technical Specifications:

| Item | Technical Specifications |

| Function | Through Complete Automatic Design, Clothes Hooks, Hangers, And Wooden Poles Can Be Assembled, Rotated, Tied, And Boxed |

| Working Voltage | Three-Phase Ac380v |

| Working Mode | 6.5 Seconds/8 (Package) |

| Rated Air Pressure | 0.5 ± 0.1mpa |

| Power | 30kw |

Automatic Wooden Hanger Making Line Features:

1. Automatic production, completely changing the original manual production mode from about 24 people/shift to 4 people/shift.

2. Advanced level, better consistency of production products, can further reduce costs and turnover costs.

Our line is complete automatic, which significantly reduces manual labor and increases production efficiency. The machinery is designed to work in harmony, with each component perfectly aligned to the next, ensuring that the hangers move smoothly from one stage to the next without delay.

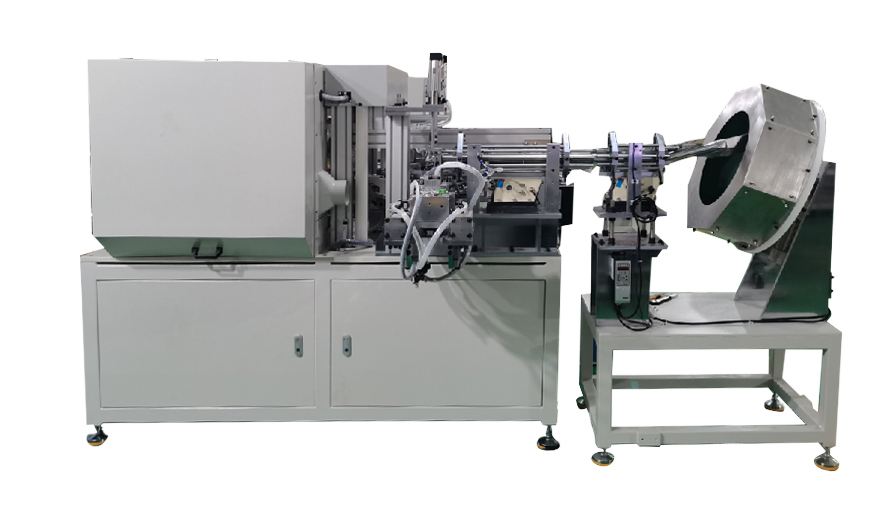

Automatic Wooden Hanger Making Line includes several key pieces of equipment that work in unison to produce high-quality wooden hangers. These include the Automatic Wood Cutting Machine, Four-Side Moulder Machine, Automatic Wooden Hanger Tenon Making Machine, Automatic Wood Hanger Shape Cutting Machine, Automatic Pit Hole Making Machine, Wooden Hanger Copying Machine, Wooden Hanger Pieces Assembling Machine, and the Hanger Hook Inserting Machine. Each machine is precision-engineered to perform its specific task with utmost efficiency and accuracy.

This line is not just about production; it's about a Complete Wooden Hanger Manufacturing Logistic Solution that streamlines the entire process from manufacturing to logistics. We understand that efficiency in production is only half the battle won; the other half lies in the effective management of the finished product. That's why our line is designed to not only manufacture the hangers but also to prepare them for bundling and distribution.

Automatic Wooden Hanger Making Line Applications:

Mass Production of Wooden Hangers: Used in large-scale manufacturing of wooden hangers for clothing retail, dry cleaning, and industrial storage.

Furniture Industry: Applied in the production of customized wooden hangers used in furniture showrooms or for premium clothing lines.

Eco-Friendly Hanger Production: Ideal for companies whose aim to produce eco-friendly and sustainable wooden hangers from renewable resources.

Custom Wooden Hanger Manufacturing: Suitable for the production of out-of-the-ordinary designed or out-of-the-ordinary branded hangers for high-end fashion designers and boutiques.

Automatic Wooden Hanger Making Line FAQs:

How many wooden hangers can the line produce per day?

The manufacturing speed depends on the specification of machines but with relation to the size, complexity of the hangers the line is capable of producing thousands of wooden hangers in a single day.

Can the line handle different types of wood?

Yes, the line can accommodate various types of wood like beech, pine, and cedar that are normally utilized in fabricating hanging items depending on the material set up and requirements.

Is there an option for diversifying the production line concerning various hanger types?

Indeed, the machine’s design is compatible with other types of hangers, such as basic, padded and even wood hangers made to order. Production line includes custom molding and finishing applications as well.

What are the main benefits of having an fully automatic wooden hanger making line?

The automatic line drastically decreases the use of identifiable manual labor, increases efficiency and speed of production, ensures uniformity in the end product, and minimizes labor expenditures. Besides, bulk production can be achieved without sacrificing the quality standard of the produced items.

Which parts and components are required for this production line on a scheduled basis?

As part of preventive maintenance, there is a need to perform cleaning and lubrication of the moving parts and proper calibration of molding equipment. Parts inspection and replacements are also needed frequently to provide necessary service.