Fully Automatic Plastic Hanger Manufacturing Line

- Product Information

Fully Automatic Plastic Hanger Manufacturing Line

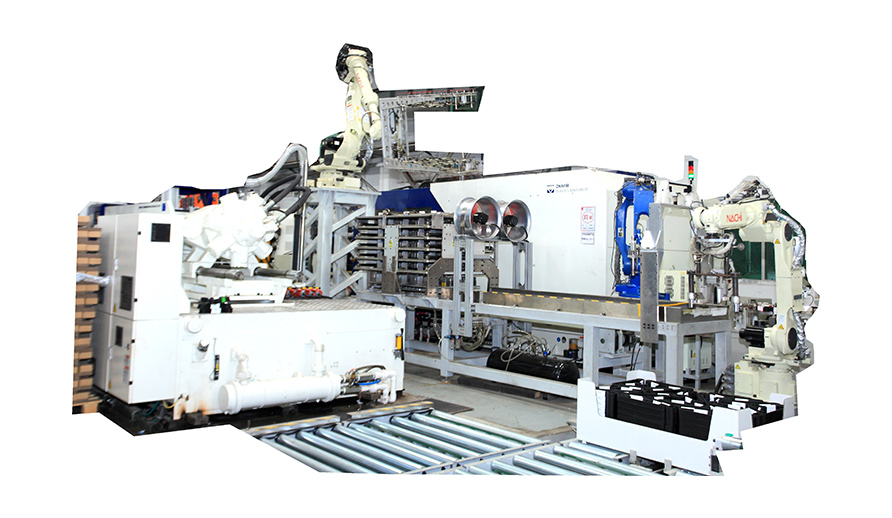

Fully Automatic Plastic Hanger Manufacturing Line is a cutting-edge, world's first fully automatic solution and the most advanced production process for plastic hangers. It can realize the collection, stacking, cooling, labeling (bundling) and automatic packing of plastic hangers without human operation and has a high degree of automation.

Fully Automatic Plastic Hanger Manufacturing Line Technical Specifications:

| Item | Technical Specifications |

| Function | Realize fully automatic production of plastic hangers, including picking up, stacking, cooling, labeling, packing, and stacking |

| Efficiency | 6S/Zha |

| Size | Designed as a complete set, depending on the actual situation |

| Power | 30KW |

Fully Automatic Plastic Hanger Manufacturing Line Features:

1. Fully automated: After injection molding is completed, all tasks are completed, and except for one person for turnover, the process is completely unmanned.

2. Fully functional: All processes can be completed in one go, without the need to change processes, sites, etc.

3. Advanced level: The world's first fully automated production line.

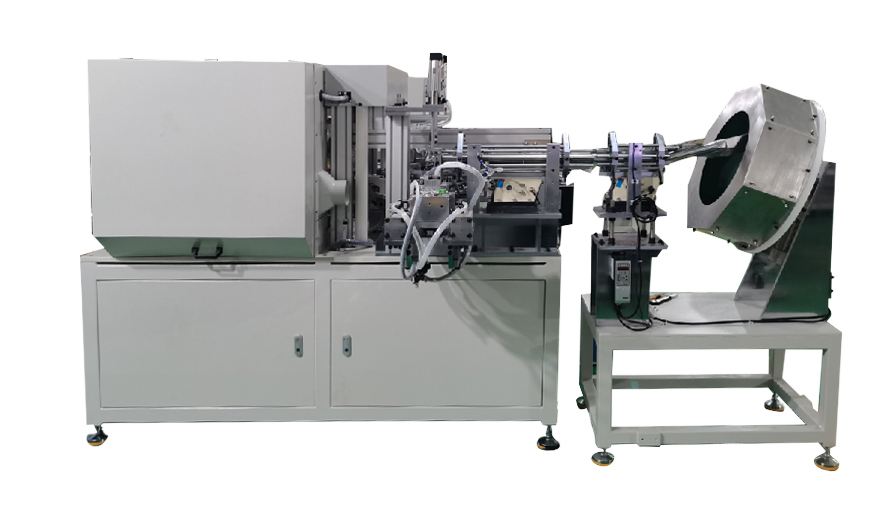

Detail Images:

Fully Automatic Plastic Hanger Manufacturing Line Applications:

Mass Production of Plastic Hangers: Such lines are used in plants to manufacture plastic hangers in volume of different shapes, size and color.

Consumer Goods Manufacturing: These systems are good for retail and household plastic hangers manufacturing companies that are developing hangers targeted at clothing and accessories.

Clothing and Textile Industry: It aids in the mass production of hangers that are used to hold clothes in retail shops, warehouses, and dry cleaning establishments.

Customized Plastic Hangers: Although such systems are applicable in different industries, they are particularly suited for the production of plastic hangers for fashion and design related companies, hotels and specialized retailers.

Packaging and logistics: The unit can also be incorporated with automated packaging logistics for easy and systematic packing and movement of finished hangers to respective warehouses.

Fully Automatic Plastic Hanger Manufacturing Line FAQ:

What is the capacity of the Fully Automatic Plastic Hanger Manufacturing Line?

The capacity differs, from one specification to another, but usually sits in the order of thousands of plastic hangers on a daily basis. The design’s complexity and the speed in production was also considered in this.

Can this manufacturing line produce different types of plastic hangers?

Answer: The line can be adjusted in accordance with requirements for producing various types of the plastic hanger suitable for garment evenly design of properties, without the specialized nurse, basic, padded, specially-shaped garment, pants, or coat hangers.

What type of materials can the line support?

The line is suitable for a variety of plastic materials used in the production of hangers, including ABS, Polypropylene, and Polyvinyl Chloride.

Is the production line complicated?

On the contrary, the line provides low maintenance, as the molding machines, conveyors, and robots are regularly inspected and maintained. Maintenance requisites are limited, but a normal check-up and greasing of components are essential.

In what way does the Fully Automatic Plastic Hanger Manufacturing Line assist to increase production output?

The system aims to minimize the amount of manually done work, so human intervention errors are virtually absent and duration of operations is greatly reduced, which can result in increased volume of production, standardization of quality of products and reduction in wage expenditures. The built-in logistics system allows the uninterrupted supply of items produced into the warehouse for packing without any waiting.