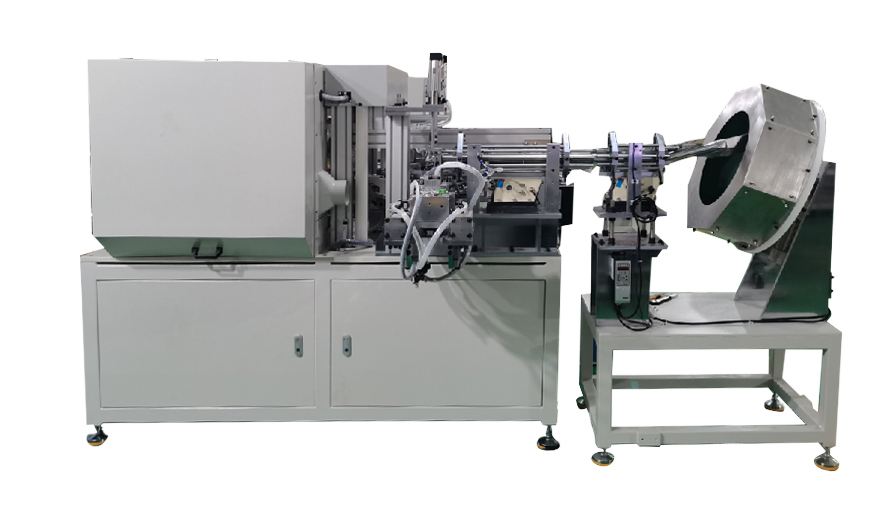

Automatic Iron Hanger Forming Machine

- Product Information

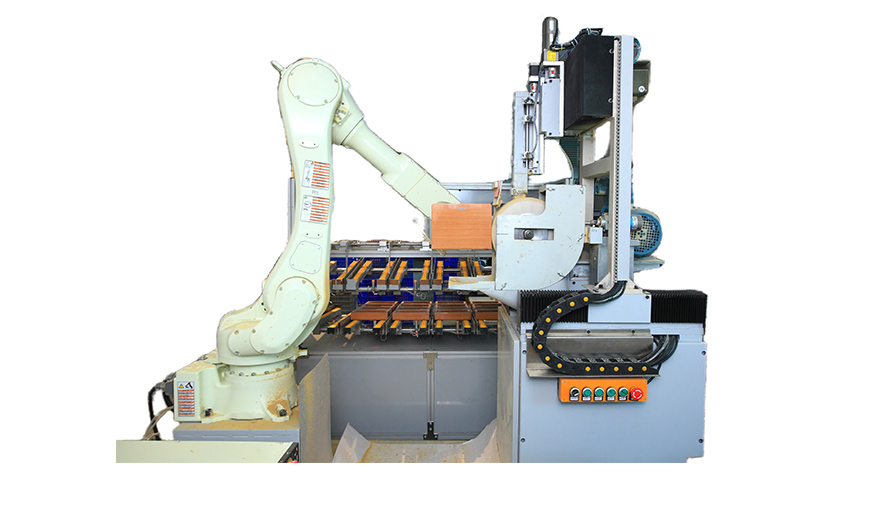

Automatic Iron Hanger Forming Machine is the new generation of precision tools for large series of iron hanger production. This new iron hanger forming machine makes it possible to produce iron hangers with diameters over ∮3.0mm, guaranteeing flexibility for various hanger dimensions. The equipment with the advanced automatic control system makes bottom hangers, which includes a straightener, feeder and a part former executed stepwise in a single arrangement. It is possible to bypass manual work with one operator handling up to six machines concurrently. This has great efficiency gains in productivity while reducing labor costs. Designed with simplicity and ease of use, iron hanger molding machine performs reliably and consistently even with minimal downtime. The system designed in this way provides for the continuous production system, hence perfecting on the workflow. Its ease of use puts its operators at an upper hand even when managing more than one such machine. These various features help to build a machine which brings and fastens production processes which in return assists manufacturers to keep up with high market requirements. The core value of the China iron hanger forming machine exporter is the provision of high-quality manufacturing solutions. Our factory has a team that is very experienced and is also well equipped with the necessary technology to provide advanced features to automation equipment.

Automatic Iron Hanger Forming Machine Technical Specifications:

| Item | Technical Specifications |

| ?Function | High End Iron Hanger (Wire Diameter>? 3.0) Fully Automatic Molding |

| Work Cycle | 4s Per Piece |

| Working Mode | Fully Automated Completion |

| Size | Approximately 4700 * 1500 * 2000mm |

| Power | 20kW |

Automatic Iron Hanger Forming Machine Equipment Features:

1. The industry has successfully developed an automatic forming machine for large wire diameter iron hangers.

2. Efficient and stable, fully automated production (7 processes completed in one go).