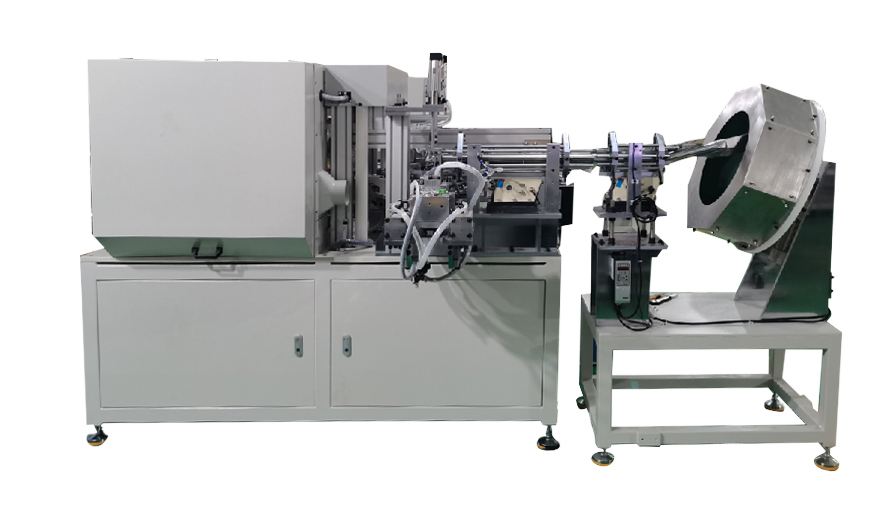

Wood Hanger Automatic Slitting Machine

- Product Information

Wood hanger automatic slitting machine is a sophisticated piece of Separation Machinery designed to enhance the efficiency of the wood hanger production process. As a reputable manufacturer, we have crafted this machine to cater to the specific needs of Wood Hanger Makers who seek to automate and optimize their manufacturing operations.

Wood hanger automatic slitting machine is a precision machine that can cut the wood into pieces to make the hanger blanks, paving the way for the next process. The reasonable design enables the equipment to produce 20,000 pieces per day, with automatic production, no need for human involvement, simple and efficient, stable and reliable.

Technical Specifications:

| Item | Technical Specifications |

| Function | Symmetrically distribute square wooden boards for wooden hangers |

| Efficiency | Approximately 1.5S/piece |

| Power | 5KW |

| Implementation method | Fully automated production |

| Size | Approximately 1500 * 2200 * 2500mm |

Equipment Features:

1. Fully automated: After connecting with the tenoning machine in the feeding process, the production is fully automated without the need for human intervention.

2. High level of advancement.

Wood hanger automatic slitting machine Application:

1. High-Precision Manufacturing: Our machine ensures that each hanger is sorted and fed with utmost precision, critical for maintaining uniformity in the quality of the final product .

2. Streamlined Production Workflow: Integrated into your production line, the Wood hanger automatic slitting machine streamlines the workflow, reducing manual handling and the associated errors, thus enhancing overall efficiency .

3. Customized Sorting Solutions: The machine can be tailored to sort hangers based on various attributes such as size, shape, or color, providing a flexible solution for diverse production requirements .

4. Increased Production Output: By automating the sorting and feeding process, our machine significantly increases the production output, allowing manufacturers to meet high demand with ease .

5. Quality Control: The Wood hanger automatic slitting machine plays a crucial role in quality control by ensuring consistent hanger dimensions and eliminating defects in the final product .

6. Labor Optimization: With the machine handling the sorting and feeding processes, labor can be redirected to other critical tasks, optimizing the use of human resources in the manufacturing environment .

Wood hanger automatic slitting machine FAQs:

How does the Wood hanger automatic slitting machine ensure the precise sorting of different hanger types?

The machine utilizes an advanced sensor system and intelligent software to accurately recognize and sort hangers based on pre-set criteria such as size, shape, and color.

What kind of maintenance does the machine require to ensure optimal performance?

Wood hanger automatic slitting machine is built for low maintenance operation. However, regular checks and servicing as per our guidelines are recommended to ensure the longevity and peak performance of the machine.

How does the Wood hanger automatic slitting machine contribute to reducing production costs?

By automating the sorting and feeding process, the machine reduces labor costs, minimizes material waste, and increases production efficiency, leading to significant cost savings over time.

What is the power requirement for the machine, and can it be customized to fit different voltages?

The machine operates on a standard industrial voltage. However, we can customize the power supply to meet specific requirements or to suit different regional voltage standards.

Finished Product: