wecan01@wecan-machine.com

|

+86-18825990919

+86-07502632972

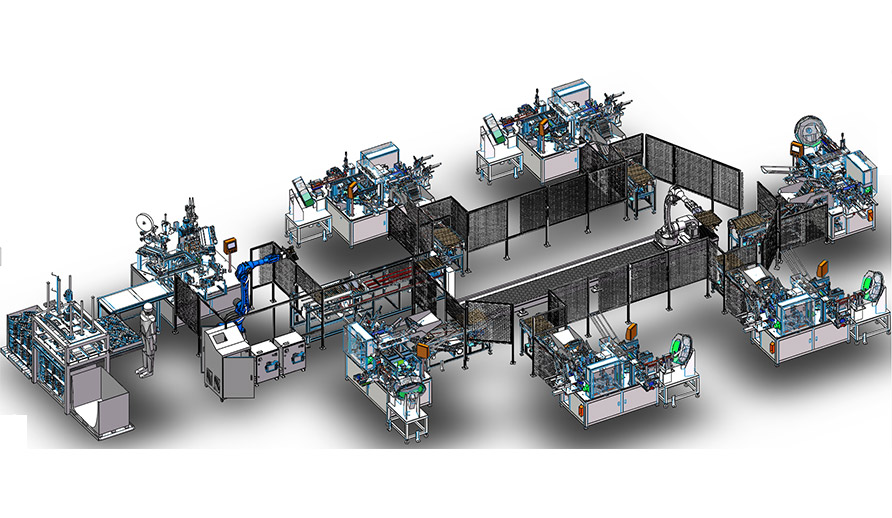

While remaining competitive in the hanger production industry, there are aspects such as system efficiency and product quality that are essential. The Complete Automatic Wooden Hanger Making Line not only incorporates these requirements best, but it also converts the traditionally labor intensive procedure into a fully automated and smooth running one. The line is engineered to take care of any and everything associated with the wooden hanger making process including raw wood treatment, cutting, polishing, assembly and even document finishing, all aimed to maximize the output with the best quality possible.

This automatic production line is very ideal for current manufacturing environments. This approach maximizes the technology fusion while optimizing the cost and eliminating bottlenecks guaranteeing online synchronization in all aspects of production. The system is versatile, as it can accommodate flat, shaped or individualized hangers so it can suit the needs of different industries. This line regularly produces reliable results not just for fashion business owners and hotel chains, but also in the realm of manufacturers and suppliers of household goods.

Optimized Manufacturing Framework

The complete automatic wooden hanger making line incorporates full production including wood cutting shaping, drilling, polishing and assembling. The raw wood is carefully shaped to be equal in size and shape and wood shaping machines cut out the actual hanger profiles from logs with a smooth edged and a clean finish. Wood polishing units abrade the uneven exhibits from the surfaces and prepare them for final assembly that consist of masking off sections of coats.

The next step of assembly follows seamlessly, wherein machines now take control of hocking, notching, and adding any other attachments required. Be it standard assortments or bespoke systems, each hanger that comes out of this system meets each specification required. The last stage consists of painting if not coating with smooth sands and sprays which will help to reinforce the look as well as provide green eco friendly options.

New Features for Better Performance

This production line has proved itself and has also showed a potential of transferring to other factories. This is because of its intelligent automation system which saves time from unnecessary human force on site intervention. Other distinguishing points include the following:

High Speed Operation: With this ability to make hundred’s of hangers within the hour, production in bulk will never have to be a problem again.

Changeable Settings: Different sizes and styles of hangers can easily be made thus providing a multilevel market.

Energy Efficient: Using greener parts, the energy cost and its impact on the environment will be decreased.

Environmentally Conscious Processing: Encourages the adoption of renewable resources and low-VOC finishing techniques.

Robust Construction: Assembled from industrial-grade materials to resist extreme wear and tear.

These features together, not only contribute towards boosting productivity of the plant but also allow every hanger to be manufactured in such a manner that it complies with the end user’s standards and expectations.

Widespread Use in Various Industries

Complete Automatic Wooden Hanger Making Line is versatile and can be used in different sectors. For garment retailers for instance, this provides a steady supply of their high-end hangers that complement the garments. Production of stylish and tough hangers that delight clients is helpful for hotels and the hospitality industry. In the renovation industry, this system helps to make nice looking hangers for home use.

This line also enables manufacturers penetrating the luxury segment and those going after the cost-targeting mass market.

What is the Benefits of the Complete Automatic Wooden Hanger Making Line?

Automation is the key in this era of globalization for organizations who want to remain in competition. There are many advantages of Complete Automatic Wooden Hanger Making Line which makes it a prerequisite in today’s fast paced manufacturing:

Enhanced productivity: Speeds up and eliminates painstaking practices thus allowing for effortless and rapid production.

Consistent Quality: Guarantees that every hanger passes through specific criteria in order to reduce wastage and defects.

Cost Efficiency: Reduces dependency on labor and operational reporting and increases output.

Sustainability: Helps foster environmentally friendly mode of production that meet the worldwide environmental standard benchmarks.

Scalability: Can be easily adjusted to meet the increased supply requirements making it possible for the businesses to expand alongside the market.

With the system in place, not only manufacturers can become more efficient and produce a better quality of product but the processes will be more environmentally friendly too, placing them at the top of the industries where they work.

Conclusion

The Complete Automatic Wooden Hanger Making Line is a state-of-the-art technology for companies that want to revolutionize their production processes. With its fully automatic function, accuracy, and high-performance characteristics, it can be a perfect instrument to manufacture large quantities of good-quality wooden hangers. For high-end retailers as well as for mass market distributors, this system works and works well and provides consistent results.

Implementing this advanced production line doesneldy improve productivity but also positively contribute to a greener mode of production that is not only efficient but also answers the current demand in the market. More than just a machine, the Complete Automatic Wooden Hanger Making Line is a leap in production efficiency and in the level of innovation and quality of the contemporary manufacturing industry.