wecan01@wecan-machine.com

|

+86-18825990919

+86-07502632972

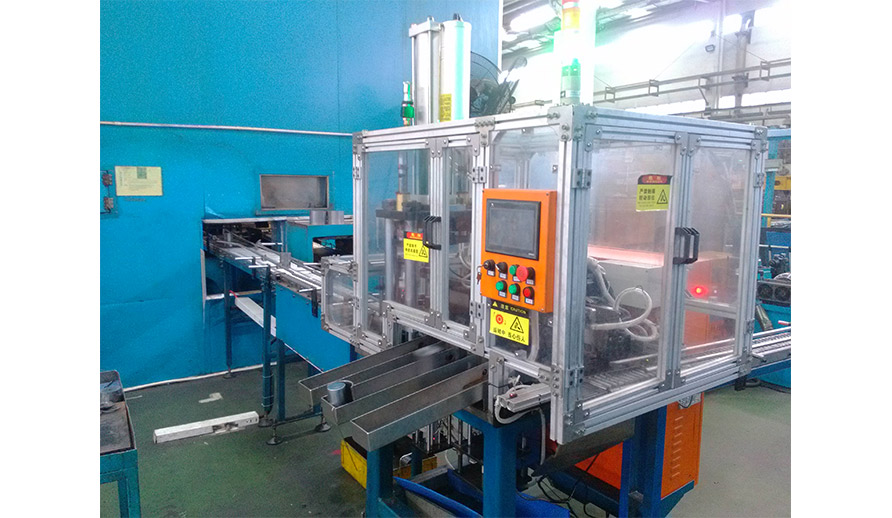

Rotors are undoubtedly one of the most valuable assets for an electric motor. In this regard, a good quality rotor lamination is key to the efficient operation and competitiveness of a motor. The Automated Rotor Laminating Machine gives the manufacturers a great opportunity to enhance precision and reproducibility of rotor cores production. Automating the stacking, alignment and lamination processes means that mistakes are thrown low, and productivity is enhanced, making it useful to firms which want to provide high-end motor parts.

Streamlining the Core Lamination Process

The old way of making rotors through paste lamination may be tedious and not necessarily perfect due to human interference. The Automatic Rotor Laminating Machine eases these setbacks by providing a machine that does all these tasks automatically and at a high speed of stacking and precise positioning. It deals with all these very common issues, where every lamination is accurately placed together and deviations are slight to create the rotor core which is optimal for electric motors.

The programs and structures of the machine give it the required capability to deal with a variety of target rotors that are of different sizes, making it easy for them to cater for clients from many industries. The machine does not disappoint and is capable of producing very small motors to be used in home equipment and very large industrial motors with the required authority.

High Accuracy Production Using Enhanced Technology

automatic rotor laminating machine is a state-of-the-art machinery design and technology that matches the standards of rotor technology of today’s world such as:

Faster Speeds: Achieves large scale rotor lamination of over thousands of rotors on a daily basis thus enhancing productivity.

Laminate Position Perfection: Guarantees that every laminate is positioned accurately during the build-up thus stall provisions increases in rotor efficiency.

Program Options: Configurable to different types of rotors with regards to volume, geometric shape and their stacking arrangement.

Robust Design: Fabricated using industrial strength materials thus providing support for continuous use.

Simple Controls: Simplified controls allow convenient operation with very low speculation on operator training.

Integratively, these innovative capabilities enable manufacturers to reduce variability in the quality of their products as they all meet the industry standard quality parameters in all the production rounds.

Multivariate Application

The automatic rotor laminating is able to service within many production units as a multipurpose machine such as:

Automotive: Guarantees and provides high performance cores of rotors of electric vehicles motors (EV).

Energy: Develops rotor units for generators as well as wind turbines, ensuring that the rising concerns for renewable energy sources are met.

Home appliances: Increases production of motors used in fridges, washing machines and air conditioning.

Industrial Appliances: Supports the lamination of rotors in heavy motors for machines and industrial appliances.

Diversified production capabilities and rotary part assemblies are some of the key reliability enhancing features that make it an invaluable solution for manufacturers operating in multiple industries.

Efficiency and Sustainability

Further, the Automatic Rotor Laminating Machine in addition to improving the productivity of operations assists in environmental conservation by reducing material and energy wastage. Such features as precision locking and automatic working pattern guarantee that the required raw materials are consumed economically thus lowering costs and pollution to the environment. Besides, its solid structure and low maintenance guarantee makes it last longer, thus suitable for industries wishing to modernize their operational systems at an affordable cost.

Reasons for acquiring the Automatic Rotor Laminating Machine

The Automatic Rotor Laminating Machine is a mundane alteration to the robotic laminating machine there already exists. With this machine certain repetitive processes where automation can be applied are streamlined and a whole range of advantages comes with it, such as:

Increase in Productivity: Processes bulk amounts of materials in accordance with standard methods at a standard rate.

Enhanced Quality: Guarantees steady lamination of structures that are able to withstand motor torques.

Decreased Costs: Less reliance on manpower and decreased material reusing mean overall production expenditures are

More Adaptable: Accepts a number of rotor patterns and shapes, and can be used in different sectors.

User-friendly: Comes with an intuitive layout making easy to work with, and easy to set it up.

By acquiring this machine, manufacturers have a fighting chance against competitors who are offering better quality and electric motors components in newer markets that are constantly changing.

Conclusion

The Automatic Rotor Laminating Machine is a modern rotor core manufacturing solution with a high degree of accuracy, great speed, and significant multi-purpose functionality. The machine is ideal for various sectors, including automotive and home appliances, as it simplifies the lamination sequence while maintaining the overall quality of the end product and lowering costs of operation.

If you are a manufacturer who intends to upgrade the capacity of your production and propose better products onto the market, the Automatic Rotor Laminating Machine offers everything; it offers increased productivity, improved manufacturing consistency, and indeed, durability. Be at the forefront of progress using this system that transforms rotor core manufacturing to a new level.