wecan01@wecan-machine.com

|

+86-18825990919

+86-07502632972

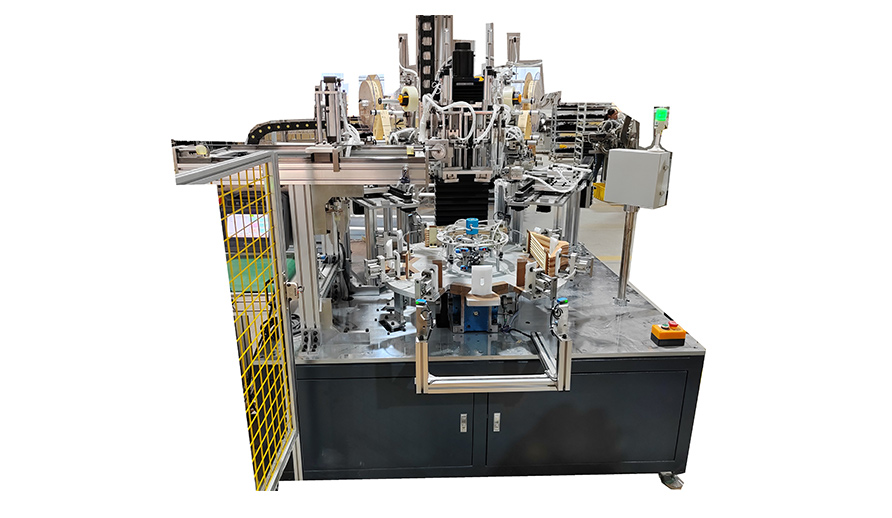

The wooden hanger packing process guarantees that the product reaches the customer safely and in good condition. In the past, the procedures of bundling and piling hangers were only done manually proportionate to the workforce available and it was extremely unreliable. The Fully Automatic Wooden Hanger Bundler has met these issues with the state-of-the-art automatic system that takes on packing tasks with speed and ease.

This packing machine does not require any movement from the operator and is able to prepare bundles of wooden hangers according to the required size. Besides improving production speed, it also ensures that all pack units are uniformly sealed ready for use in stores or for shipping. Additionally, the bundler commends great efficiency as a result of being able to work at high speeds which is ideal in this era where there are great volumes of hangers to be worked on.

Cost effective network of processes such as loading the hangers into the required bundles and finally locking the bundles into position is achievable given the automated system. manufacturers can have assurance that all bundles will be able to comply with all quality and beauty standards of the product which in turn improves their branding. This machine is made with tough materials and it is easy to operate making it applicable for any business dealing with wooden hanger manufacturing.

This bundler is suitable to work with a variety of hanger sizes and designs which adds to its versatility. Bundling of regular hangers for retail shops or various designs of hangers targeting high-end hospitality clients is not a problem with the machine for it always provides the same results. It was designed to be compact so that it can be easily incorporated into production systems that already exist without consuming more space than necessary.

In addition to that, the fully automatic wooden hanger bundler makes it possible for its users to practice green operations because it minimizes the amount of alien packaging material that would have been used if done manually. In the same context, this machine does a good communication in environmental matters by utilizing, films and or straps more efficiently then they would have been done enhancing the bond of sustainability and lower operating costs.

This machine now becomes a dependable and time saving solution to industries like retail, hospitality and home goods where package is highly appreciated in transacting goods to clients. As long as this machine is used, there is guaranteed a tightly and neatly packed bundle whether this is hangers to be shipped directly or hungers to be stored in bulk.

The revolutionary Fully Automatic Wooden Hanger Bundler from now onward is the perfect tool for wooden hanger manufacturers who wish to package sanctified products in packaging that speaks professionalism. From the description one realizes how time-consuming and cumbersome it could have been not advancing technology if financial and human resource needs were not a concern. With a little capital outlay towards this advanced purchase solution, enterprises can reduce losing money on human resources and improve processing work and provide customers hangers wrapped in ribbons professionally.

For companies striving to remain competitive in the marketplace, this bundler is in the direction of automation and packaging perfection.