wecan01@wecan-machine.com

|

+86-18825990919

+86-07502632972

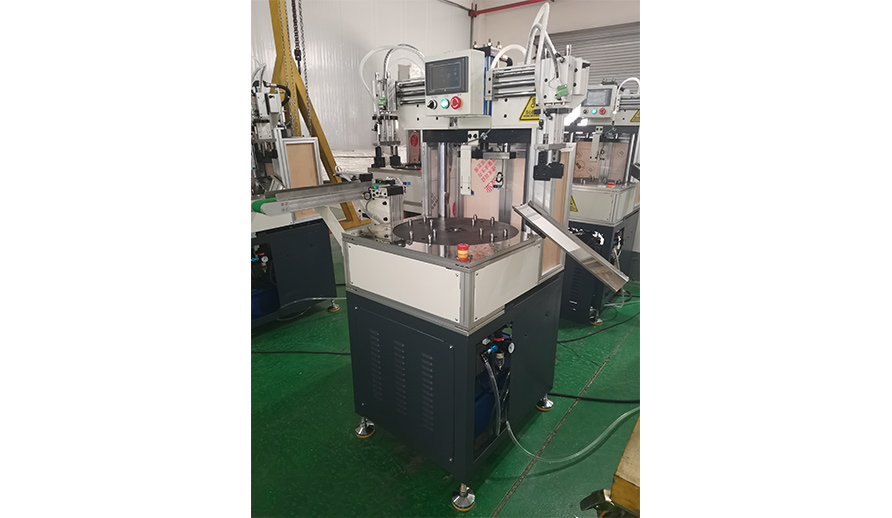

In the making of electric motors, the accuracy and the speed of assembly of components, especially of stators, are extremely important. A new machine that works as an automatic tool and greatly advances this phase of the process is the Four-Station Stator Insertion Press Machine. The coil and insulative insertion task is an absolutely complicated one, but this machine is set to change that. This machine is effective in producing more output with its four zones working at the same time, able to produce a collection of components without compromising the quality.

The functioning of the machine is on a chain system in which the stations are arranged vertically such that each station carries out one or more operations during the coil insert. During the loading of the stator cores to incorporating the coils, and even compressing them in their rightful places, every process is guaranteed to be without flaws. The multi-station configuration allows for barrels to be processed one after the other, increasing the maximum linear movement speed which aids in greater production for industrial lines with minimal cost. Its user-friendly controls allow the operator to set his preferred settings and make minor adjustments rapidly, minimizing time wasted and promoting a much smoother operation.

The four-station stator insertion press machine is an appropriate solution for businesses that manufacture electric motors as it allows stators for a variety of applications to be produced. The On-The-Go Stator Insertion Press can be used to quickly produce electric components which can further be utilized in vehicles as well as household equipment. No matter how complex the design of the product might be, this machine provides a secure and sturdy solution that enhances the construction. Its programmable features would enable the company to change the dimensions of the coils, the pattern of the winding as well as the insertion force as per the requirements of the product.

To be precise, this machine has been designed especially to last long and be reliable. The parts used to manufacture these machines are industrial-grade along with the large pressing which allows the machine to carry on function even in [harsh] conditions. Operator safety and the protection of the product during transport are guaranteed through the protection mechanism from hazards and systems that align the components with great precision. In addition to all this, with the use of such components which are energy saving helps to bring down the cost when running the operations while at the same time supporting the idea of eco friendly products.

The pressing machine, which incorporates four stator insertion presses, is a significant investment for industries if they are looking at upgrading their assembly lines. manufacturers will have the ability to cut down on the amount of time spent on coil insertion which will automatically incur lower labor expenses, enhance efficiency and reduce fallibility. This is not only an increase in efficiency but also a means for companies to cater to the rising requirement of electric motor components in various sectors.

Electric vehicles, electric power thrust and renewable energy systems are taking over the market and hence the need for electric motors is high and ever increasing. To bridge such gaps in production and to comply with the need, the Four-Station Stator Insertion Press Machine is able to insert in stators at greater speed , ensures precision work being done and is also able to cater for mass production. This in turn also guarantees that the electric motors work efficiently as the stators are always produced to perfection which enhances the final product.

Conclusion

The Four-Station Stator Insertion Press Machine is revolutionary and brings ease for industries engaged in electric motors’ manufacturing. It integrates three important features- high speed, precise manufacturing and increased array of activities which enables firms to reduce the time taken to produce the stators and ensure quality is the same irrespective of scale production. This unit is aimed at disturbing all the established players in the market catering to the automobile, industrial and home appliance segment.

The primary focus is on the essentiality of increasing investment in the advanced manufacturing solution. By investing in such kind of manufacturing solutions, a business can remain competitive, reduce costs and also boost its production capabilities. The same sentiment was echoed when a four-station stator insertion press machine was acquired and described it as not an upgrade rather it's a necessity towards where automated assembly of stators is headed.